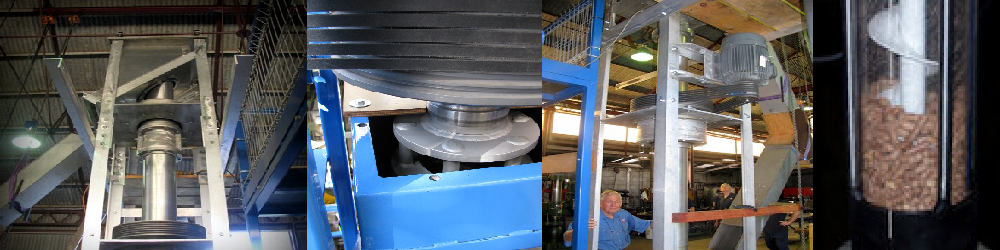

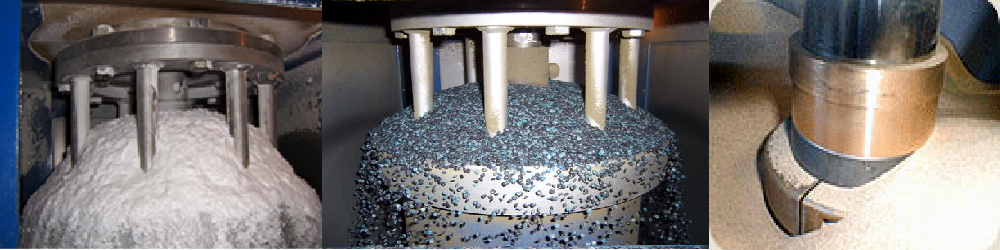

Olds Elevators™ -

The innovative Olds Elevator™ is a Vertical Bulk Material Conveyor and volumetric feeder which efficiently and economically transports bulk solids while providing inherent protection against dust explosion. Considered to be a revolutionary bulk handling technology, it’s an ingenious advance in the field of bulk materials handling.